NEWS RELEASE 20 NOVEMBER 2025

Modern Assays Validate Historical Copper Grades at Tannenberg

HIGHLIGHTS

· High-grade copper intercepts confirmed: Modern assays from six (of 47) archived drill cores confirm historical grades with intercepts of 1.0-3.7 m at 0.7-2.7% copper and 10-55 g/t silver

o Ro 23: 1.5 m at 2.7% copper and 55 g/t silver.

o Ro 45: 2.4 m at 1.4% copper and 18 g/t silver.

o Ro 25: 1.0 m at 2.0% copper and 41 g/t silver.

o Ro 17: 1.3 m at 1.2% copper and 24 g/t silver.

o Ro 15: 3.7 m at 1.2% copper and 17 g/t silver.

o Ro 38: 1.8 m at 0.7% copper and 15 g/t silver.

· Mineralisation thicker than 1940 historical estimate: New intercepts demonstrate widths of 1.0‑3.7 m, significantly exceeding the maximum thickness used in the 1940 Historical Estimate (refer to announcement dated 20 October 2025)

· First Modern Assays for over 40 years: Results from re-sampling of 1980s drill core from holes located up to 12 km apart show comparable or higher grades and thicker intercepts than original analysis, validating historical work and demonstrating resource upside and scale potential

· Confirms GreenX epigenetic model: Results confirm that mineralisation extends beyond the narrow Kupferschiefer shale horizon into the footwall and hanging wall, consistent with KGHM's Polish operations (589,000tpa copper production) located on the same basement architecture

· Quality assured program: All samples meet strict QAQC standards, including >90% core recovery, with analysis by ISO/IEC 17025 accredited laboratory

· Significant program ahead: Initial assay results from six of 47 archived cores now reported, with the historical core re-sampling program and results reporting to continue through to Q1 2026

GreenX Metals Limited (ASX:GRX, LSE:GRX, GPW:GRX, Germany-FSE:A3C9JR) (GreenX or Company) is pleased to announce the first batch of assay results from its historical core logging and sampling program at the Tannenberg Copper Project (Tannenberg or Project) in Germany. These results further validate historical exploration data from the 1980s and confirm that mineralisation widths are thicker than those used in the 1940 Historical Estimate (refer to ASX announcement dated 20 October 2025).

GreenX's Chief Executive Officer, Mr Ben Stoikovich, commented: "These initial results are very pleasing, with the grades, including 2.7% copper intercept at Ro 23, consistent with or slightly better than the historical results; the thicker widths, including 3.7 metres at Ro 15, being in line with our geological model and understanding of Kupferschiefer systems; and lastly the scale, with these initial drill holes located up to 12 kilometres apart.

As previously announced to the market, a large amount of historical exploration data is already available for the Project, and these initial results are an important first step in applying modern techniques to validate and build on the historical exploration as we begin to fully define the Project's scale and importance.

With the majority of the core program still ahead of us, and the potential for new discoveries in 18 previously unassayed holes, we're building a compelling case for a significant copper resource in one of Europe's most accessible mining districts."

EXPLORATION HISTORY AT TANNENBERG AND PROJECT RATIONALE

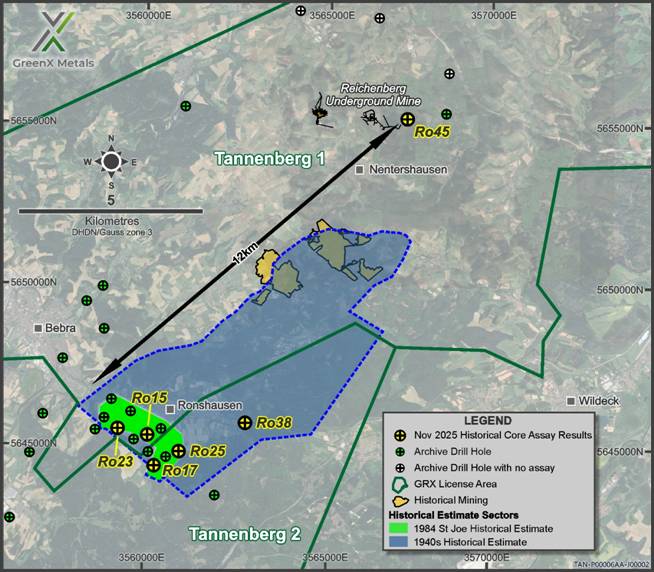

The Richelsdorf Mining District has been subject to significant historical drilling, with a 95-hole drilling program completed in the mid-1930s by the National Socialist Government. GreenX discovered the drill database from this program in various German archives (refer to announcement dated 11 September 2025). Subsequent exploration from the 1970s onwards included copper and oil exploration, with 47 relevant archived cores now available for modern analysis (Figure 1). Of the 47 archived cores in the program, 18 holes have no recorded historical assays, representing targets for potentially new mineralisation discovery. The remaining 29 holes have limited historical assaying, typically focused on a narrow 5 m-wide interval across the Kupferschiefer shale, with the true extent of the potential mineralised interval untested.

Historical exploration was constrained by the prevailing geological model, which assumed copper mineralisation was syngenetic and restricted to the thin Kupferschiefer shale. This limitation meant sampling focused on a narrow interval, typically only 5 m around the Kupferschiefer horizon, rather than the up to 90 m intervals that characterise economic Kupferschiefer deposits in Poland today.

The modern understanding of Kupferschiefer copper systems, as demonstrated by KGHM Polska Miedz (KGHM) operations in Poland, supports GreenX's epigenetic model. KGHM produces over 589,000 tonnes of copper per annum (Source: KGHM Annual Report 2024) from deposits similar to those at Tannenberg, with mineralisation often occurring up to 30 m above and 60 m below the Kupferschiefer shale horizon. KGHM's operations are located on the same basement architecture as the Tannenberg Project.

Figure 1: Map of reported assay results where greater than 90% of the historical core over the target interval was available from the archived core.

2025 CORE SAMPLING RESULTS

The results announced here are historical core assay results where over 90% of historical core was available over the target sample interval from an initial six of the total 47 holes that form part of the program. The results have confirmed that mineralisation is present in widths which are thicker than just the narrow Kupferschiefer shale. In this program, mineralisation widths range from 1.0 to 3.7 meters. These results show that the mineralisation is thicker than only the Kupferschiefer strata included in the 1940 Historical Estimate. Not only do these results confirm that the analyses performed by St Joe in the 1980s were accurate, but also that the concept of syngenetic mineralisation restricted to the narrow Kupferschiefer is geologically incorrect. The results are consistent with the expectation that considerably more mineralisation exists at the Tannenberg project than reflected in the 1940 Historical Estimate, which was restricted to reporting mineralisation in the Kupferschiefer shale only (refer to announcement dated 20 October 2025).

Table 1: Results of the 2025 relogging and sampling campaign.

| Locality |

Hole ID |

Intersect (m) |

Cu |

Ag |

Core Recovery |

||

| From |

To |

Interval |

|||||

| Ronshausen |

Ro 15 |

285.60 |

289.30 |

3.70 |

1.2 |

17 |

96% |

| Ro 17 |

481.25 |

482.55 |

1.30 |

1.2 |

24 |

92% |

|

| Ro 23 |

366.00 |

367.50 |

1.50 |

2.7 |

55 |

93% |

|

| Ro 25 |

533.38 |

534.39 |

1.01 |

2.0 |

41 |

100% |

|

| Ro 38 |

536.25 |

538.00 |

1.75 |

0.7 |

15 |

100% |

|

| Nentershausen |

Ro 45 |

268.00 |

270.37 |

2.37 |

1.4 |

18 |

100% |

Most holes for the six sets of assay results reported are located in the Ronshausen area, where the 1940 Historical Estimate was subsequently validated by the 1980's Historical Estimate produced by St Joe (refer to announcement dated 20 October 2025). One of the assay results is from hole Ro 45 located near Nentershausen to the north of the area covered by the 1940 Historical Estimate, in the vicinity of the Reichenberg mine.

Figure 2: The locations of the historical estimates and the reported assay results from the initial batch of six holes where greater than 90% of the historical core over the target interval was available from the archived core.

RELOGGING AND RESAMPLING PROCESSES

The core program currently underway involves re-logging, re-assaying, hyperspectral scanning and the collection of petrophysical measurements for historical core from 47 drillholes completed from the 1980s. Where appropriate, assaying and hyperspectral scanning will cover up to 30 m above and 60 m below the Kupferschiefer shale. The core was logged and sampled in accordance with modern industry best practices at Palsatech Sala (Sweden). Analysis of the samples was performed at SGS in Ankara (Türkiye) who are part of the well-respected SGS testing, inspection and certification company. The laboratory is accredited to ISO/IEC 17025 standard. GreenX further validated the process using its own Quality Assurance and Quality Control program.

The core used in the program had been stored for 40 years by the Hessisches Landesamt für Naturschutz, Umwelt und Geologie (HLNUG). This Hessen state authority is responsible for preserving assets such as these for explorers and interested parties in future decades. The core was stored in suitable facilities and was found to be in excellent condition. HLNUG permitted GreenX to transport, analyse, and sample the core under strict conditions, ensuring the quality of the work and requiring that some core be left for future users. The core will be returned to the archives upon completion of the program.

The core was processed at a specialist mining industry facility in Sala (Sweden) that utilises specialist equipment and personnel, and where industry best practice procedures are already established. GreenX reports all exploration results in accordance with the JORC Code (2012) (JORC Code). To achieve appropriate Quality Assurance and Quality Control standards, sampling requires appropriate systems to be used.

|

|

|

|

|

Figure 3 (Left to Right, Clockwise): Owner's team training and evaluation (hole Ro 45, Assays for the visual core above have been reported in this announcement) by GreenX, including Dr Prof Gregor Borg in Sala (Sweden); Core transportation from the HLNUG archive; and core handling in Sala (Sweden).

Upcoming Work Programs

These results are the first assays to be released as part of GreenX's ongoing archive core logging and sampling campaign, which is part of a broader exploration program at Tannenberg, which includes:

· Logging, assaying, and hyperspectral scanning of remaining historical core (ongoing);

· Reprocessing and analysis of historical geophysical data (ongoing);

· Collation and digitisation of historical geological, mine development, and production data (ongoing); and

· Twin drilling to verify historical estimates and establish a mineral resource estimate in accordance with the JORC Code.

EXERCISE OF OPTION OVER TANNENBERG

As a result of the progress made on the Project to date, GreenX intends to acquire 90% of the fully diluted share capital of Group 11 Exploration GmbH (Group 11), a private German company which holds the Tannenberg exploration licences, pursuant to the terms of the Joint Venture and Earn-in Agreement (Agreement) as announced on 2 August 2024. Under the terms of the Agreement, GreenX can elect to acquire 90% of the fully diluted share capital of Group 11 on or before 31 December 2025.

On electing to acquire 90% of Group 11, GreenX will be required to pay A$3,000,000 to the vendors in GreenX shares (based on the higher of the 10-day VWAP or A$0.30 per Share). The vendors' 10% interest in Group 11 will then be free carried until the completion of a feasibility study by Group 11 or GreenX. For further details, please refer to the announcement dated 2 August 2025.

To watch an interview by Mr Ben Stoikovich, GreenX's CEO, relating to this announcement, please visit https://www.voxmarkets.com/articles/interview-with-greenx-metals-ceo-ben-stoikovich-218474a

ENQUIRIES

| +44 207 478 3900 |

Sapan Ghai Chief Commercial Officer - UK

|

| Kim Eckhof Investor Relations - UK / Germany

|

Kazimierz Chojna Investor Relations - Poland

|

Competent Person Statement

The information in this announcement that relates to Exploration Results is based on information compiled by Dr Matthew Jackson, a Competent Person who is a Member of the Australian Institute of Mining and Metallurgy. Dr Jackson is a Technical Consultant for GreenX and is a holder of unlisted options in the Company. Dr Jackson has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves'. Dr Jackson consents to the inclusion in this announcement of the matters based on his information in the form and context in which it appears

Forward Looking Statements

This release may include forward-looking statements, which may be identified by words such as "expects", "anticipates", "believes", "projects", "plans", and similar expressions. These forward-looking statements are based on GreenX's expectations and beliefs concerning future events. Forward looking statements are necessarily subject to risks, uncertainties and other factors, many of which are outside the control of GreenX, which could cause actual results to differ materially from such statements. There can be no assurance that forward-looking statements will prove to be correct. GreenX makes no undertaking to subsequently update or revise the forward-looking statements made in this release, to reflect the circumstances or events after the date of that release.

In relation to the disclosure of visual information/estimates, GreenX cautions that the images displayed are for general illustrative purposes only, and that the samples displayed, and visual methods of mineralisation identification and estimation of mineral abundance should not be considered as a proxy or substitute for laboratory analysis. Laboratory analysis would be required for the grades of mineralisation. Visual information also potentially provides no information regarding impurities or deleterious physical properties relevant to valuations. Assays for the visual core above have been reported in this announcement.

The information contained within this announcement is deemed to constitute inside information as stipulated under the Regulation 2014/596/EU which is part of domestic law pursuant to the Market Abuse (Amendment) (EU Exit) Regulations (SI 2019/310) ("UK MAR"). By the publication of this announcement via a Regulatory Information Service, this inside information (as defined in UK MAR) is now considered to be in the public domain.

Appendix 1: Exploration Results and JORC Tables

Table 1: Results of the 2025 relogging and sampling campaign

| Locality |

Hole ID |

Intersect (m) |

Cu |

Ag |

Core Recovery |

||

| From |

To |

Interval |

|||||

| Ronshausen |

Ro 15 |

285.60 |

289.30 |

3.70 |

1.2 |

17 |

96% |

| Ro 15 |

285.86 |

289.31 |

3.45 |

1.0 |

13 |

|

|

| Ro 17 |

481.25 |

482.55 |

1.30 |

1.2 |

24 |

92% |

|

| Ro 17 |

481.51 |

482.42 |

0.91 |

1.4 |

11 |

|

|

| Ro 23 |

366.00 |

367.50 |

1.50 |

2.7 |

55 |

93% |

|

| Ro 23 |

365.48 |

367.58 |

2.10 |

2.7 |

48 |

|

|

| Ro 25 |

533.38 |

534.39 |

1.01 |

2.0 |

41 |

100% |

|

| Ro 25 |

533.38 |

534.39 |

1.01 |

1.8 |

N/A |

|

|

| Ro 38 |

536.25 |

538.00 |

1.75 |

0.7 |

15 |

100% |

|

| Ro 38 |

536.25 |

538.00 |

1.75 |

0.7 |

16 |

|

|

| Nentershausen |

Ro 45 |

268.00 |

270.37 |

2.37 |

1.4 |

18 |

100% |

| Ro 45 |

268.00 |

270.00 |

2.00 |

1.6 |

19 |

|

|

Figures in Bold and black are 2025 results, and figures in regular typeface are 1980s drilling results as reported by St Joe (previously reported in accordance with JORC. Refer to announcements dated 2 August 2024 and 28 April 2025).

Table 2: Historical drill hole information (1980's Drilling Campaign)

| Hole ID |

Easting |

Northing |

Elevation (m MSL) |

Dip (°) |

Depth (m) |

| Ro 15 |

4348595 |

5647200 |

255 |

90 |

351 |

| Ro 17 |

4348767 |

5646242 |

305 |

90 |

551 |

| Ro 23 |

4347684 |

5647433 |

300 |

90 |

380 |

| Ro 25 |

4349554 |

5646656 |

331 |

90 |

553 |

| Ro 38 |

4351640 |

5647472 |

249 |

90 |

559 |

| Ro 45 |

4356946 |

5656716 |

407 |

90 |

289 |

Note: Coordinates are DHDN / 3-degree Gauss-Kruger zone 4 (previously reported in accordance with JORC. Refer to announcements dated 2 August 2024 and 28 April 2025).

Table 2: Drill hole assays (2025 Logging and Resampling Program)

| Hole ID |

Intersect (m) |

Cu (%) |

Ag (ppm) |

||

| From |

To |

Interval |

|||

| Ro 15 |

285.6 |

286.24 |

0.64 |

0.44 |

6 |

| Ro 15 |

286.24 |

287 |

0.76 |

0.71 |

11 |

| Ro 15 |

287 |

287.56 |

0.56 |

0.73 |

10 |

| Ro 15 |

288.2 |

288.76 |

0.56 |

3.09 |

39 |

| Ro 15 |

288.76 |

289.3 |

0.54 |

2.39 |

37 |

| Ro 17 |

481.25 |

481.6 |

0.35 |

0.32 |

5 |

| Ro 17 |

481.6 |

481.96 |

0.36 |

1.43 |

17 |

| Ro 17 |

481.96 |

482.3 |

0.34 |

1.54 |

31 |

| Ro 17 |

482.3 |

482.55 |

0.25 |

1.60 |

52 |

| Ro 23 |

366 |

366.5 |

0.5 |

0.85 |

17 |

| Ro 23 |

366.5 |

367 |

0.5 |

1.00 |

75 |

| Ro 23 |

367 |

367.5 |

0.5 |

1.00 |

74 |

| Ro 25 |

533.38 |

533.89 |

0.51 |

3.15 |

66 |

| Ro 25 |

533.89 |

534.39 |

0.5 |

0.73 |

15 |

| Ro 38 |

536.25 |

536.66 |

0.41 |

0.91 |

15 |

| Ro 38 |

536.66 |

537 |

0.34 |

1.70 |

35 |

| Ro 38 |

537 |

537.5 |

0.5 |

0.34 |

7 |

| Ro 38 |

537.5 |

538 |

0.5 |

0.30 |

8 |

| Ro 38 |

538.35 |

538.7 |

0.35 |

0.30 |

6 |

| Ro 38 |

538.7 |

539 |

0.3 |

0.39 |

7 |

| Ro 38 |

539 |

539.5 |

0.5 |

0.48 |

10 |

| Ro 45 |

268.34 |

269 |

0.66 |

2.10 |

33 |

| Ro 45 |

269 |

269.63 |

0.63 |

1.53 |

21 |

| Ro 45 |

269.63 |

270 |

0.37 |

1.48 |

10 |

| Ro 45 |

270 |

270.37 |

0.37 |

1.06 |

8 |

Note: Only assay results equal to or greater than 0.3% copper are included in this table.

JORC Code, 2012 Edition - Table 1 Report

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

| Criteria |

JORC Code explanation |

Commentary |

| Sampling techniques |

Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. |

1980's Drilling Campaign All 1980's analyses reported in this announcement were from diamond drill core. The core for the holes was 47 mm diameter in all cases, except Ro 17 and Ro 15 where core was 60 mm in diameter. Due to the historic nature of the drilling results reported herein, it is not possible to comment on the quality of the drilling used to produce the results described.

Sampling of ¼ core was conducted during multiple exploration phases between 1980 and 1987 within the licence area by St Joe.

The 1980's information was collated from original hard copy reports from that era and a State Survey Database. Assays, geological logging and gamma ray logs were conducted by St Joe Explorations and Mansfeld AG. No other information is available for the exploration drilling.

2025 Logging and Resampling Program

The core used for the program had been sampled to varying degrees during the 40 years in storage. Sampling restrictions were placed on the program by the owners. As such, two sampling protocols were used: ¼ core sampling and sliver sampling.

Where ¼ core sampling was employed, the program used industry standard methods to take 25% of the core which was originally extracted from the hole.

Sliver sampling was employed where only 25% of the core was available in order to leave core in the box to maintain the archive correctly. In this case 20% of the remaining 25% was sampled using a specialist saw. Where this resulted in low sample mass, the interval lengths were increased in order to maintain suitable representivity.

For the intervals from most holes (Ro 38, Ro 17, Ro 25 and Ro 45), ¼ core was sampled for the majority of the samples and sliver sampling for the remaining narrow intervals.

For the hole Ro 23, 79% of the sampling was conducted using the sliver method and the remaining using ¼ core.

For the intervals from Ro 15 only sliver sampling was used.

A handheld XRF was used to assist with confirming the representivity of the sliver sampling and determining sample.

|

|

|

Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. |

1980's Drilling Campaign No details covering the representivity of the samples for 1980's assays were reported by the authors.

2025 Logging and Resampling Program Due to the extremely fine-grained mineralisation and matrix of Kupferschiefer Mineralisation (eg Rahfeld, 2018), the heterogeneity of the sampled materials is known to be extremely low. By comparison with other deposits, fundamental sampling error (FSE) is likely to be between 2-5% coefficient of variation (Absalov, 2011). This means that the introduction of error from sub-sampling of the core and samples will be negligible and very low sample sizes are suitable for assessing grade.

In order to further validate the low FSE, in the sliver samples. pXRF measurements were made at spacings of 5-10cm where sliver samples were taken. The results of the pXRF measurements confirmed that a very low error was found and that the use of sliver samples is suitable for assessing grade.

A handheld XRF was used only for validation of sliver samples and assisting with selection of sample intervals. The Olympus Vanta (V2MR) configured with the GeoChem(3) calibration. A reading time of 40 seconds was used. A blank standard or CRM was analysed daily before the start of work. Procedures were in place to ensure correct operation.

|

|

|

Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. |

2025 Logging and Resampling Program Sampling ¼ core followed industry standard procedures. The same side of the core was sampled throughout each hole. The samples were cut using an automated saw designed for core cutting in order to eliminate any sample loss.

The use of sliver sampling is uncommon in many deposits, although known to be used in some sedimentary hosted copper deposits similar to the Kupferschiefer. Due to the extremely fine-grained mineralisation and matrix of Kupferschiefer Mineralisation (eg Rahfeld, 2018), the heterogeneity of the sampled materials is known to be extremely low. By comparison with other deposits, FSE is likely to be between 2-5% coefficient of variation (Absalov, 2011). This means that the introduction of error from sub-sampling of the core and samples will be negligible and very low sample sizes are suitable.

|

| Drilling techniques |

Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). |

1980's Drilling Campaign The samples were all taken from core and the core for the holes was 47 mm diameter in all cases, except Ro 17 and Ro 15 where core was 60 mm in diameter. No other details of the drilling are available. |

| Drill sample recovery |

Method of recording and assessing core and chip sample recoveries and results assessed.

|

Core recoveries for the relevant intercepts are as follows: · Ro 23 93% · Ro 38 100% · Ro 17 92% · Ro 25 100% · Ro 35 86%. Not reported, below 90%. · Ro 19 75%. Not reported, below 90%. · Ro 15 96% · Ro 45 100%

The recoveries reported here are measured from the core available for sampling in 2025.

|

|

|

Measures taken to maximise sample recovery and ensure representative nature of the samples. |

Not known. |

|

|

Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

It is believed that low core recoveries in some cases may have been caused by researchers removing small sections of the core that contained elevated copper. For that reason, a core recovery limit of 90% was used to select which holes to report.

Due to the same possibility of past researchers removing copper enriched parts, it is possible that the intervals announced here may under-report copper. The addition of the 90% core recovery selection criteria has limited that effect. |

| Logging |

Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. |

Geological and geotechnical logging has been completed according to industry best practice and would be suitable to support Mineral Resource Estimation. Note that JORC Mineral Resources not reported in this announcement. |

|

|

Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. |

Geological and geotechnical logging is qualitative. Wet and dry core photos have been taken. |

|

|

The total length and percentage of the relevant intersections logged. |

1980's Drilling Campaign The entire hole was logged, the target zone is typically 2 m thick.

2025 Logging and Resampling Program All available core was logged. The amount of available core always included the mineralised T1 stratigraphic horizon and was a minimum of 10m above and below that unit. In most cases at least 90m of core was logged and some cases the entire hole.

|

| Sub-sampling techniques |

If core, whether cut or sawn and whether quarter, half or all core taken. |

1980's Drilling Campaign Samples were sawn using ¼ core. 2025 Logging and Resampling Program Where ¼ core was sampled, industry standard sampling methods were used.

Where sliver samples were taken, a small rock saw was used to take 20% of the ¼ core that was available.

In all cases the same side of the core was sampled from top to bottom.

|

|

|

If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. |

N/A

|

|

|

For all sample types, the nature, quality and appropriateness of the sample preparation technique. |

1980's Drilling Campaign Methods unknown.

2025 Logging and Resampling Program Industry standard and accredited techniques were used in all cases. Samples were weighed, then crushed in a jaw crusher to 75% passing 2 mm. The crushed sample was then split using a rotary splitter to 250 g. The sub sample was then pulverised to 85% passing a 75 µm.

All procedures were accredited to ISO/IEC 17025 standard.

|

|

|

Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. |

1980's Drilling Campaign Methods unknown.

2025 Logging and Resampling Program Screen tests were performed and reported for both crushing and pulverising stages. The results showed that comminution met and exceeded the standards above. |

|

|

Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. |

1980's Drilling Campaign Methods unknown.

2025 Logging and Resampling Program Industry standard quality control methods were used. GRX used coarse and pulp duplicates were inserted at a frequency of 1/50 each. Field duplicates were not used due to restrictions on the proportion of core available for sampling.

The maximum error between crush duplicates was found to be 2.0% and 0% for Cu and Ag respectively, which supports the view the FSE is low and that sliver sampling was representative of the mineralisation.

|

|

|

Whether sample sizes are appropriate to the grain size of the material being sampled. |

1980's Drilling Campaign Methods unknown, but given that ¼ core was sampled, samples are likely to meet modern industry standards.

2025 Logging and Resampling Program For the ¼ core samples masses were between 0.19 kg and 7.89 kg. This is appropriate.

For the sliver samples, masses were between 0.1 kg and 0.84 Kg. This is appropriate given the low FSE, validation by pXRF and low error seen in coarse duplicates.

|

| Quality of assay data and laboratory tests |

The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. |

1980's Drilling Campaign Geochemical analysis was carried out by Robertson Research Ltd, Wales, however the precise nature quality and appropriateness of the assaying is unknown. The precise nature quality and appropriateness of the assaying is unknown.

2025 Logging and Resampling Program Industry standard and accredited procedures were used. All samples were analysed using a four-acid digestion with an Inductively Coupled Plasma - Atomic Emission Spectroscopy (ICP-AES) finish. Where analyses were found to be above detection limits, an Atomic Absorption Spectroscopy (AAS) finish was used. All procedures were accredited to ISO/IEC 17025 standard. |

|

|

For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. |

A handheld XRF was used only for validation of sliver samples and assisting with selection of sample intervals. The Olympus Vanta (V2MR) configured with the GeoChem(3) calibration. A reading time of 40s was used. A blank standard or CRM was analysed daily before the start of work. Procedures were in place to ensure correct operation.

|

|

|

Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. |

Quality Control samples were added at a rate of 10%. For every 100 samples, 4 Certified Reference Materials were used, two Pulp duplicates, two crush duplicate and two blanks were inserted.

Certified reference materials were matrix matched where possible and included ore and cut-off grade materials for copper and silver. |

| Verification of sampling and assaying |

The verification of significant intersections by either independent or alternative company personnel.

|

1980's Drilling Campaign The 1980's drilling significant intersections were verified using the 2025 logging and sampling program.

2025 Logging and Resampling Program No verification completed.

|

|

|

The use of twinned holes. |

No twinned holes reported. |

|

|

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. |

1980's Drilling Campaign 10% Electronic data records were verified against paper records, focussing on ore grades.

2025 Logging and Resampling Program 10% Electronic data records were verified against paper records, focussing on ore grades.

|

|

|

Discuss any adjustment to assay data. |

No adjustments made. |

| Location of data points |

Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. |

Location accuracy is unknown. The location of holes drilled by St Joe Explorations comes from collar tables in historical reports. All other collar locations come from State/Federal databases. |

|

|

Specification of the grid system used. |

1980's Drilling Latitude and Longitude in degree, minutes and seconds were provided by St Joe Explorations.

|

|

|

Quality and adequacy of topographic control. |

Unknown |

| Data spacing and distribution |

Data spacing for reporting of Exploration Results. |

1980's Drilling Between 400 m to 700 m.

|

|

|

Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. |

N/A, JORC Mineral Resources not reported. |

|

|

Whether sample compositing has been applied. |

No compositing applied |

| Orientation of data in relation to geological structure |

Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. |

The target Kupferschiefer layer is flat to slightly dipping, vertical drilling therefore intercepts at right angles and is appropriate. |

|

|

If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

No sampling bias introduced by intersection angles. |

| Sample security |

The measures taken to ensure sample security. |

1980's Drilling Campaign Methods not known.

2025 Logging and Resampling Program Full chain of custody tracking was completed for all transportation of core and samples.

|

| Audits or reviews |

The results of any audits or reviews of sampling techniques and data. |

No audits completed. |

Section 2 Reporting of Exploration Results

(Criteria in the preceding section also apply to this section.)

| Criteria |

JORC Code explanation |

Commentary |

|

| Mineral tenement and land tenure status |

Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. |

The Tannenberg 1 licence is held 100% by Group 11 Exploration GmbH. The licences were awarded on the 6th June 2025 for three years and has now been extended for a further three years to 6 June 2028. The licence is free from overriding royalties and native titles interests. There are historical mine workings within the licence area, but no known historical sites of cultural significance outside of mining. The Tannenberg 2 exploration licence is held 100% by Group 11 Exploration GmbH. The licence was granted effective 22 April 2025 and is valid for three years also until 6 June 2028.

Within and surrounding both licence areas, there are environmental protections zones with differing levels of protections. There are small areas identified as Natura 2000 Fauna Flora Habitat Areas and Bird Sanctuaries. Other environmental protection designated areas include Nature Reserves, National Natural Monuments, Landscape Protection Area, and Natural Parks. Based on due diligence and discussions with various stakeholders and consultants, the presence of environmental protection areas does not preclude exploration or eventual mining if conducted in accordance with applicable standards and regulations.

The landform across the license area comprises mostly of farmland, forested areas, and small towns and villages. |

|

|

|

The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. |

The licences are in good standing. |

|

| Exploration done by other parties |

Acknowledgment and appraisal of exploration by other parties. |

Exploration was carried out by St Joe Explorations (in JV with the Broken Hill Pty Co Ltd later BHP-Utah) between 1980 and 1987. Two projects were undertaken. The Richelsdorf project within the licence area as well as the Spessart-Rhoen project 85 km to the south. Hole IDs starting with 'Ro' were drilled by St Joe Explorations.

Exploration in the 1930's was carried out by Mansfeld AG and resulted in 95 drill holes which were used to establish 3 mines in the area, with recommendations for the opening of a further 2 which never materialised.

Historical mining took place within the licence area. Mining activities ceased in the 1950's. |

|

| Geology |

Deposit type, geological setting and style of mineralisation. |

Mineralisation is of the classic Kupferschiefer type (copper slate) within the Permian Zechstein Basin of Germany and Poland. The Zechstein Basin is hosted within the Southern Permian Basin ("SPB") of Europe. The SPB is an intracontinental basin that developed on the northern foreland of the Variscan Orogen. Very high-grade copper mineralisation is generally associated with the Kupferschiefer shale unit. However, minable copper mineralisation also occurs in the footwall sandstone and hanging wall limestone units in Poland. Mineralisation can be offset from the shale by up to 30 m above and 60 m below. |

|

| Drill hole Information |

A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: easting and northing of the drill hole collar elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar dip and azimuth of the hole down hole length and interception depth hole length. |

All drill hole collar information has been provided in Table 1 of Appendix 1. |

|

|

|

If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. |

All drill hole collar information has been provided in Table 1 of Appendix 1. |

|

| Data aggregation methods |

In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. |

Industry standard methods used. No cut-off grade or high cut was applied. |

|

|

|

Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. |

Industry standard methods used. No cut-off grade or high cut was applied. |

|

|

|

The assumptions used for any reporting of metal equivalent values should be clearly stated. |

No metal equivalents reported. |

|

| Relationship between mineralisation widths and intercept lengths |

These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. |

Drilling was perpendicular to mineralisation and therefore intercept thicknesses are the same as mineralisation thicknesses. |

|

|

|

If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). |

Drilling was perpendicular to mineralisation and therefore intercept thicknesses are the same as mineralisation thicknesses. |

|

| Diagrams |

Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. |

Relevant maps were included on pages, 2, and 4. Also refer to maps included in announcements dated 2 August 2024 and 28 April 2025. |

|

| Balanced reporting |

Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. |

All relevant and material results have been reported. |

|

| Other substantive exploration data |

Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. |

All substantive results are reported. Geological logs and downhole gamma logs are not reported here. |

|

| Further work |

The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). |

The Company plans to take the following next steps to further seek to verify the historical estimates identified at Tannenberg: · Relogging and sampling of additional archived drill core (underway at the time of writing) · Further review and validation of historical data. · Twinning (repeat drilling) of certain holes. · Mineral Resource Estimation and reporting according to best practice and the JORC Code.

|

|

|

|

Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. |

These diagrams are included in the main body of this release. |

|